Boilers Feed Industries in India: Water and Wastewater Management with STP, ETP, WTP, WWTP & RO Systems

Boilers feed industries form a vital backbone of India's industrial infrastructure, supplying high-pressure steam essential in manufacturing, power generation, chemicals, textiles, and pharmaceuticals. In Maharashtra, which houses several industrial zones like Pune, Nagpur, and Aurangabad, extensive boiler-based operations drive the demand for high-purity water.

The industrial landscape of Maharashtra relies heavily on efficient boiler-feed water systems. These operations demand reliable water quality management to ensure uninterrupted productivity and prevent scaling, corrosion, or energy losses. Due to this, the state has witnessed increased investment in water and wastewater treatment technologies, especially in regions with high industrial density.

Boilers Feed Industries Rely Heavily on High-Quality Water for Steam Generation and Efficiency

Boiler feed water is crucial in generating steam that powers various manufacturing processes. The quality of this water directly affects the boiler's lifespan and performance. Impurities like dissolved salts or gases can lead to scaling and corrosion, reducing thermal efficiency.

Industries use water for multiple applications, from steam generation, cooling, and cleaning to process integration. Given this high dependency, treated water that meets stringent quality standards becomes essential. Hence, technologies like Reverse Osmosis (RO), Demineralization (DM), and filtration are widely implemented to condition the feed water before use.

Wastewater Arises from Pre-Treatment, Cleaning, Blowdown, and Process Discharges in Boiler Systems

Boiler operations inherently produce wastewater at various stages of the process. During pre-treatment, backwashing of filters and chemical dosing units create effluent streams. Additionally, periodic blowdowns to remove impurities from the boiler drum generate high-temperature waste containing concentrated salts.

"Water is not just a resource; it's the lifeblood of operation, efficiency, and longevity in boiler feed industries. Treated properly, it prevents corrosion, scaling, and energy losses—ensuring that every drop contributes to productivity."

Other wastewater sources include condensate drainage, chemical cleaning of boilers, and water used for cooling and surface washdowns. These streams are often laden with oils, heavy metals, and treatment chemicals, making them unsuitable for direct discharge without proper treatment. The wastewater composition varies depending on the industry and water source used.

Boiler Operations Discharge Chemical-Rich, High-Temperature Wastewater That Requires Specialized Treatment

The wastewater from boiler feed industries typically includes blowdown water, high in total dissolved solids (TDS), silica, and phosphates. If left untreated, this water can damage infrastructure and pollute natural water bodies.

Other effluents may contain chemical residues from pre-treatment processes like softening or dosing with antiscalants and oxygen scavengers. Contaminated cooling water and cleaning fluids further contribute to the volume of industrial wastewater, each requiring customized treatment methods to remove harmful substances before reuse or disposal.

Treatment Involves Mechanical, Chemical, and Biological Systems for Safe Reuse or Discharge of Wastewater

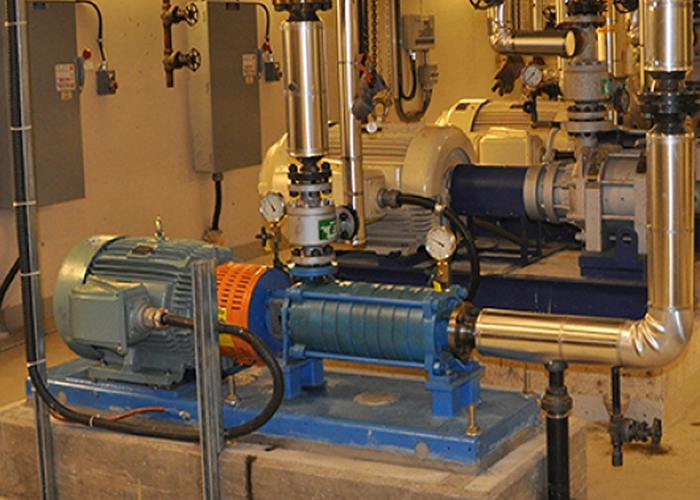

Industries implement a combination of technologies to manage wastewater. Effluent Treatment Plants (ETPs) remove suspended solids, oils, and heavy metals, while Sewage Treatment Plants (STPs) handle domestic waste from industrial zones.

Advanced systems like membrane filtration, Reverse Osmosis (RO), and Multi-Effect Evaporators (MEE) are applied for high-recovery and zero liquid discharge (ZLD) goals. These solutions protect the environment and help conserve water, which is a critical resource in large-scale operations.

Modern Treatment Technologies Enable Resource Recovery and Sustainability in Boiler Feed Operations

Many boiler-feed industries are shifting toward sustainable models by investing in cutting-edge wastewater treatment technologies. Systems like Ultrafiltration (UF), Nanofiltration (NF), and RO are standard setups for high-purity water reuse.

Automation and IoT integration now allow real-time water quality monitoring, enhancing operational control. Industries are increasingly adopting Zero Liquid Discharge (ZLD) systems to recover up to 95% of wastewater, reducing dependence on freshwater sources and environmental risks.

Comprehensive Design, Installation, and Maintenance of Custom Water Treatment Plants for Industries

We offer tailored water and wastewater treatment solutions for boiler feed industries, from consultation to execution. Our services include system design, supply, installation, and ongoing maintenance of STP, ETP, WTP, and RO plants suited for industrial needs.

Our team of experts analyzes your water quality and operational requirements to deliver efficient systems that ensure compliance, reliability, and cost-effectiveness. We also provide automation and remote monitoring options, ensuring your water treatment plant runs smoothly with minimal manual intervention.

Conclusion: Boiler Feed Industries and Water Treatment Plants

Sustainable Water Management in Hospitals Ensures Safety, Compliance, and Environmental Stewardship

Boiler feed industries rely on consistent, treated water to function effectively. They generate significant volumes of wastewater, which, if untreated, can lead to environmental and operational issues. Modern technologies—ranging from RO and STP to ZLD systems—allow these industries to treat and reuse water, supporting sustainability goals. With tailored services and ongoing innovation in the field, efficient water and wastewater management is no longer optional—it's a necessity.