Comprehensive Water and Wastewater Treatment Solutions for Tanneries Using STP, ETP, RO, WTP, WWTP, and ZLD Systems

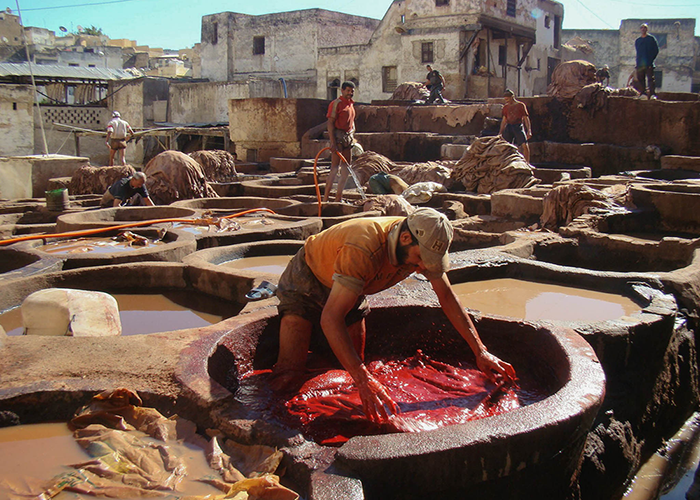

India holds a prominent place in the global leather market, and tanneries are the backbone of this industry. These units are primarily concentrated in Tamil Nadu, Uttar Pradesh, West Bengal, and Maharashtra. They play a crucial role in processing raw hides into finished leather for domestic consumption and exports, contributing significantly to employment and GDP.

In Maharashtra, cities like Mumbai, Kolhapur, and Solapur have seen the establishment of both traditional and modern tanneries. These facilities provide livelihoods to thousands, but they also pose significant environmental challenges, especially concerning water usage and pollution. As regulations tighten, many tanneries are adopting cleaner practices and investing in advanced wastewater treatment solutions.

Tanneries require large volumes of water across various leather processing stages, from soaking to finishing.

Water is an essential resource in tannery operations. From the initial cleaning and soaking of raw hides to processes like liming, deliming, tanning, dyeing, and finishing, water is used at almost every step. These processes demand water not just in large quantities but also of specific quality to prevent interference with the chemicals used.

Besides core processing, water is also required in ancillary systems like boilers, cooling, and equipment cleaning. Poor water quality can lead to defects in leather or reduce the efficiency of chemical reactions. Hence, consistent access to clean water and systems to reuse treated water is essential to maintain output quality and operational sustainability.

Various leather processing steps discharge heavily contaminated and chemically laden wastewater into effluent streams.

The tanning industry generates a significant amount of wastewater during its multistage processing. Initial processes like soaking release organic waste and blood residues. Liming and unhairing discharge lime, sulfides, and suspended solids into the wastewater. The delimiting and bating processes further introduce ammonium salts and enzymes into the mix.

In tanneries, water is not just a raw input—it's the vehicle that carries the process forward. Responsible water use and efficient wastewater treatment are essential not only for regulatory compliance but for protecting the environment and preserving the future of leather craftsmanship.

The most hazardous waste arises from tanning operations, particularly chrome tanning, which releases chromium compounds. Post-tanning operations such as dyeing and finishing add synthetic dyes, fats, and other chemicals to the effluent. Combined, these streams create a complex, high-load wastewater that requires careful segregation and treatment to meet environmental standards.

Tannery wastewater includes chromium, sulfides, suspended solids, and high biological and chemical oxygen demand.

Tannery effluents are among the most complex industrial wastewater. They contain a wide range of pollutants, including chromium (from tanning), sulfides (from unhairing), fats, proteins, salts, and dyes. These substances result in high COD (Chemical Oxygen Demand) and BOD (Biological Oxygen Demand), making the wastewater highly toxic and resistant to natural degradation.

Wastewater from the liming stage often contains high levels of sulfides and calcium compounds, while effluents from chrome tanning carry trivalent chromium. The post-tanning processes contribute oils, surfactants, and organic dyes. Without proper treatment, these discharges can pollute local water bodies, harm aquatic life, and pose a risk to human health.

Tanneries use multistage treatment plants, including ETPs and chrome recovery units, to manage wastewater effectively.

To manage their complex effluents, tanneries employ Effluent Treatment Plants (ETPs) that involve multiple stages of treatment. Primary treatment includes pH adjustment, coagulation, and sedimentation to remove suspended solids and precipitate metals like chromium. Many tanneries use chrome recovery units to reclaim and reuse chromium from tanning baths.

Secondary treatment typically involves biological methods—either aerobic or anaerobic—to reduce organic load. Tertiary treatment may include filtration systems such as sand, activated carbon, and sometimes advanced oxidation to remove remaining contaminants. The sludge generated is handled carefully to prevent leaching. Such structured treatment processes are essential for meeting discharge norms.

Tanneries integrate RO, MBR, and ZLD systems for water recycling and reduced freshwater dependence.

Modern tanneries are increasingly embracing technology to minimize freshwater consumption and reuse treated wastewater. Reverse Osmosis (RO) is widely used after tertiary treatment to recover clean water from effluent, reducing the demand on municipal or groundwater sources.

Membrane Bioreactors (MBRs) combine biological and filtration processes to enhance treatment efficiency, especially in high-load wastewater. Some units implement Zero Liquid Discharge (ZLD) systems, where all wastewater is treated, and no effluent is released into the environment. These solutions not only ensure regulatory compliance but also improve operational sustainability and reduce water procurement costs.

We deliver turnkey water treatment systems tailored to the tannery industry's complex wastewater challenges.

We specialize in designing and implementing customized water and wastewater treatment systems for the tanning industry. Our solutions include ETPs, chrome recovery systems, WTPs, RO plants, and complete ZLD setups based on site-specific requirements. Our team conducts detailed assessments to ensure compliance and efficiency.

Whether your unit is a small-scale tannery or a large industrial complex, we offer scalable, automated, and cost-effective solutions. From initial consultation and design to installation and after-sales support, we provide end-to-end services. Our goal is to help you meet environmental norms while optimizing water use and treatment costs.

Conclusion: Water Treatment is Key to Sustainable Growth of Tanneries

Conclusion: Water Treatment is Key to Sustainable Growth of Tanneries

Tanneries form an integral part of the leather industry, but their water-intensive processes demand equally strong wastewater management. Untreated effluents pose risks to both the environment and industry reputation. With rising regulatory pressures and environmental awareness, adopting efficient water treatment systems is no longer optional.

Technologies like ETPs, RO, MBR, and ZLD offer real, practical solutions to manage and reuse water efficiently. By partnering with experts who understand the industry's unique needs, tanneries can not only ensure compliance but also work towards sustainable production, cost savings, and long-term success.